HRC Couplings

A semi-elastic flexible coupling designed for use with machinery driven by standard IEC motors

- Overview

- Dimensions

- Technical

"HRC" is a registered trademark of the Fenner Group, but has become a widely used, generic term, to describe this coupling design.

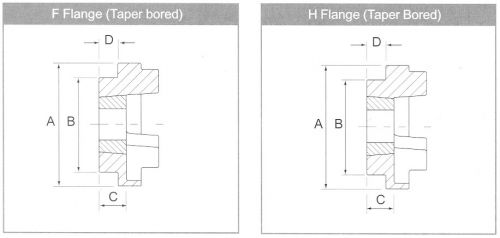

HRC couplings consist of 2 cast-iron halves attached to shafts by means of either hub mount (H Flange) or face mount (F Flange) taper bushes.

Between these two halves is a rubber "spider" that serves as a shock absorber

HRC Couplings allow for a limited parallel misalignment (0.5mm) and axial misalignment (1.5mm).

Can be used on shafts with taper bushes to 90mm bore or shafts up to 130mm if bored through with keyway.

Basic coupling dimensions

| Coupling No | Nominal torque | Overall dia. | Hub dia. | Element | Parallel misalignment | Weight | Assembled length | |

| Ring dia. | Width | |||||||

| A | B | G | FF,FH,HH | |||||

| Nm | mm | mm | mm | mm | mm | kg | mm | |

| 70 | 31 | 69 | 60 | 31 | 18.5 | 0.3 | 1 | 65.5 |

| 90 | 80 | 85 | 70 | 32 | 22.5 | 0.3 | 1.17 | 69.5 |

| 110 | 160 | 112 | 100 | 45 | 29.5 | 0.3 | 5 | 82.5 |

| 130 | 315 | 130 | 105 | 50 | 36.5 | 0.4 | 5.46 | 89.5 |

| 150 | 600 | 150 | 115 | 62 | 40.5 | 0.4 | 7.11 | 107.5 |

| 180 | 950 | 180 | 125 | 77 | 49.5 | 0.4 | 16.65 | 142.5 |

| 230 | 2000 | 225 | 155 | 99 | 59.5 | 0.5 | 26.05 | 164.5 |

| 280 | 3150 | 275 | 206 | 119 | 74.5 | 0.5 | 50.05 | 207.5 |

Suitable taper bush and shaft sizes

| Coupling No | Maximum bore | Shoulder width | |||

| D | C | ||||

| mm | in | mm | mm | ||

| 70 | 1008 | 25 | 1 | 20 | 23.5 |

| 90 | 1108 | 28 | 1.1/8 | 19.5 | 23.5 |

| 110 | 1610 | 42 | 1.5/8 | 18.5 | 26.5 |

| 130 | 1610 | 42 | 1.5/8 | 18 | 26.5 |

| 150 | 2012 | 50 | 2 | 23.5 | 33.5 |

| 180 | 2517 | 60 | 2.1/2 | 34.5 | 46.5 |

| 230 | 3020 | 75 | 3 | 39.5 | 52.5 |

| 280 | 3525 | 100 | 4 | 51 | 66.5 |

Selection of HRC Couplings

1. Design power = motor power x service factor

2. Select suitable coupling based on shaft speed and power from the table below

3. Check that this coupling can accommodate taper bushes big enough for your shaft, if not select a larger coupling.

Service factor

| Electric motors | Internal Combustion Engines | |||||

| Hours/day | <8 | 8-16 | >16 | <8 | 8-16 | >16 |

| Uniform load | 1 | 1.12 | 1.25 | 1.25 | 1.4 | 1.6 |

| Moderate shock | 1.6 | 1.8 | 2 | 2 | 2.24 | 2.5 |

| Heavy shock | 2.5 | 2.8 | 3.12 | 3.12 | 3.55 | 4 |

Coupling power ratings

| Speed | Coupling size | |||||||

| rpm | 70 | 90 | 110 | 130 | 150 | 180 | 230 | 280 |

| 100 | 0.33 | 0.84 | 1.68 | 3.3 | 6.28 | 9.95 | 20.9 | 33 |

| 200 | 0.66 | 1.68 | 3.35 | 6.6 | 12.6 | 19.9 | 41.9 | 65 |

| 400 | 1.32 | 3.35 | 6.7 | 13.2 | 25.1 | 39.8 | 83.8 | 132 |

| 600 | 1.98 | 5.03 | 10.1 | 19.8 | 37.7 | 59.7 | 126 | 198 |

| 720 | 2.37 | 6.03 | 12.1 | 23.8 | 45.2 | 71.6 | 151 | 238 |

| 800 | 2.64 | 6.7 | 13.4 | 26.4 | 50.3 | 79.6 | 168 | 264 |

| 960 | 3.17 | 8.04 | 16.1 | 31.7 | 60.3 | 95.5 | 201 | 317 |

| 1200 | 3.96 | 10.1 | 20.1 | 39.6 | 75.4 | 119 | 251 | 396 |

| 1440 | 4.75 | 12.1 | 24.1 | 47.5 | 90.5 | 143 | 302 | 475 |

| 1600 | 5.28 | 13.4 | 26.8 | 52.8 | 101 | 159 | 335 | 528 |

| 1800 | 5.94 | 15.1 | 30.2 | 59.4 | 113 | 179 | 377 | 594 |

| 2000 | 6.6 | 16.8 | 33.5 | 66 | 126 | 199 | 419 | 660 |

| 2200 | 7.26 | 18.4 | 36.9 | 72.6 | 138 | 219 | 461 | 726 |

| 2400 | 7.92 | 20.1 | 40.2 | 79.2 | 151 | 239 | 503 | |

| 2600 | 8.58 | 21.8 | 43.6 | 85.8 | 163 | 259 | 545 | |

| 2880 | 9.5 | 24.1 | 48.3 | 95 | 181 | 286 | ||

| 3000 | 9.9 | 25.1 | 50.3 | 99 | 188 | 298 | ||

| 3600 | 11.9 | 30.1 | 60.3 | 118 | 226 | |||

| Nominal torque | 31.5 | 80 | 160 | 315 | 600 | 950 | 2000 | 3150 |

| Max torque (Nm) | 72 | 180 | 360 | 720 | 1500 | 2350 | 5000 | 7200 |